Why Choose Precision Balls for Industrial Applications?

- Low Friction: Reduces friction between moving parts, improving machinery efficiency.

- High Load Capacity: Designed to withstand significant stress and heavy loads.

- Consistency: Uniform size and shape deliver consistent performance across uses.

- Versatility: Ideal for applications like ball mills, industrial machinery, and coated balls in France.

- Durability: Extends machinery lifespan by minimizing wear and tear.

With advanced manufacturing techniques and stringent quality controls, our steel balls meet the highest industrial standards. Trust us to deliver reliable solutions for your specific application needs.

This meticulous process ensures the production of high-quality precision balls for demanding applications.

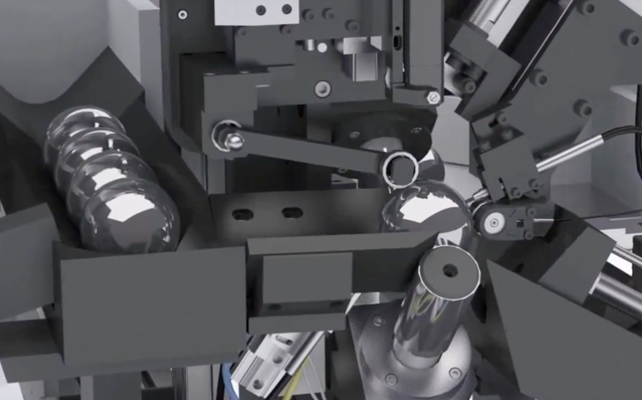

Process Flow of Balls:

- Raw Material Storage: Materials like steel, or plastic are securely stored, ensuring readiness for production.

- Wire Cutting: Raw wire is cut into precise lengths to prepare for shaping.

- Flashing: Excess material is removed, refining the cut wire for the next phase.

- Heat Treatment: Balls are treated with controlled heating and cooling to enhance hardness and durability.

- Grinding: Balls undergo precision shaping to achieve exact dimensions and a uniform surface finish.

- Lapping: Surface refinement ensures optimal roundness and a flawless finish for superior performance.

- Final Inspection: Each ball undergoes rigorous quality checks to confirm compliance with industrial standards and specifications.

This meticulous process ensures the production of high-quality precision balls for demanding applications.

Discover the diverse world of balls by SKP Bearing Industries – brass, glass, stainless steel, and beyond!

Stainless Steel balls

Brass Balls

Ceramic Balls

Glass Balls

INNOVATION AT ITS FINEST

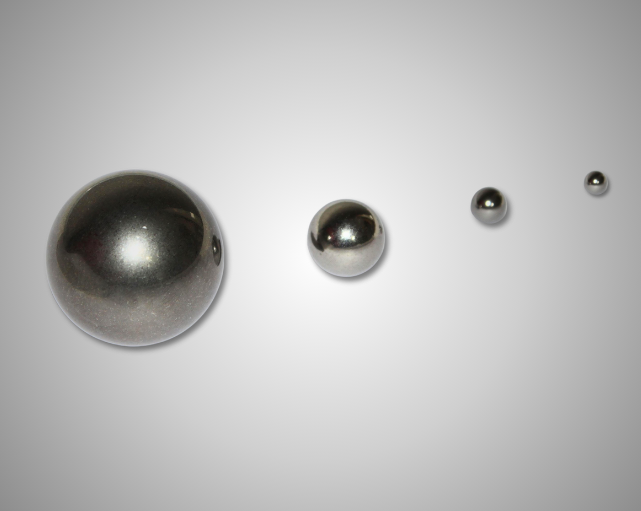

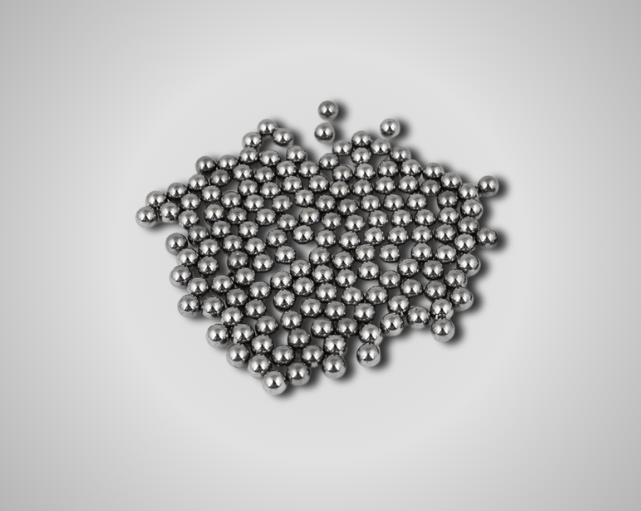

Industrial Steel Balls

Production capacity: 4.5 billion pieces annually.

Even in the most demanding environments, these balls provide consistent performance across automotive and aerospace applications. Our cutting-edge manufacturing facilities ensure.

Miniature Balls

Material: Stainless Steel (SS), SAE 52100, EN31.

Application: Roll-on applicators, sprays, pens, and inhalers.

Industry: pharmaceutical and cosmetics industry.

Miniature balls are essential parts of consumer goods and precision instruments. These small balls, made of high-quality stainless steel and other long-lasting materials, are ideal for applications that require precise and dependable performance.

Whether used in medical devices like inhalers or everyday items like pens, our miniature balls ensure smooth operation and long-term durability while adhering to the pharmaceutical, industrial, and cosmetic industries' strict specifications.

Satellite Balls

Application: Media components.

Industry: Abrasive industry.

Satellite balls, made from EN31 and stainless steel, are specialized components designed for use in the abrasive industry.

Their robust construction allows them to withstand harsh operating conditions, making them essential in media applications. These balls are engineered for maximum durability and efficiency, ensuring that your abrasive processes are optimized for performance and longevity.

SS Balls & Chrome Balls

Application: Steering columns, bearings, seating mechanisms.

Industry: Bearing, automotive, aerospace.

These balls are designed to withstand wear and corrosion, resulting in exceptional performance in high-stress environments. Whether in steering columns or precision bearings, they help vehicles and machinery run smoothly and safely, ensuring reliability and efficiency across a wide range of applications.

Their robust construction allows them to withstand harsh operating conditions, making them essential in media applications. These balls are engineered for maximum durability and efficiency, ensuring that your abrasive processes are optimized for performance and longevity.

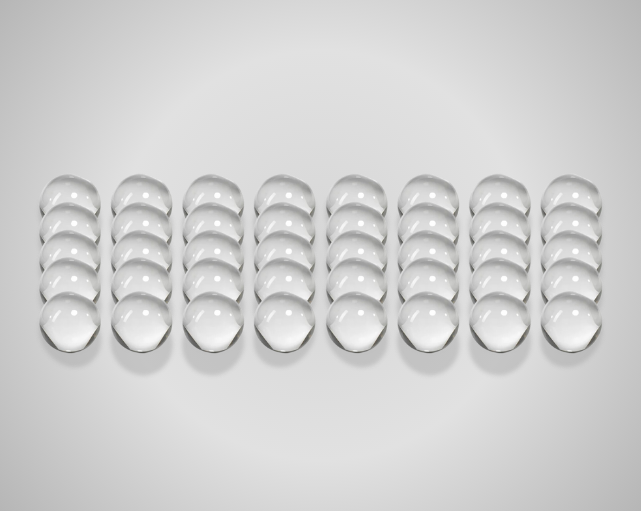

Glass Balls

Application: Roll-on applicators, rust preventive sprays.

Industry: Pharmaceutical.

Glass balls are versatile components that are used in a variety of applications, including the pharmaceutical industry.

These balls, made of high-quality glass, or plastic, are ideal for use in roll-on applicators and anti-rust sprays. Their smooth surface and precise dimensions ensure efficient operation and consistent results, making them an ideal choice for manufacturers seeking dependable and long-lasting solutions.

Plastic Balls

Application: Roll-on applicators, sprays.

Industry: Pharmaceutical, cosmetic.

The plastic balls from SKP France come in a variety of colors to meet different functional and aesthetic needs.

They are lightweight and adaptable. Mostly utilized in the cosmetic and pharmaceutical sectors, these balls are essential to items like sprays and roll-on applicators. They are perfect for high-precision applications because of their smooth finish and reliable quality, which guarantees long-term durability and easy operation.

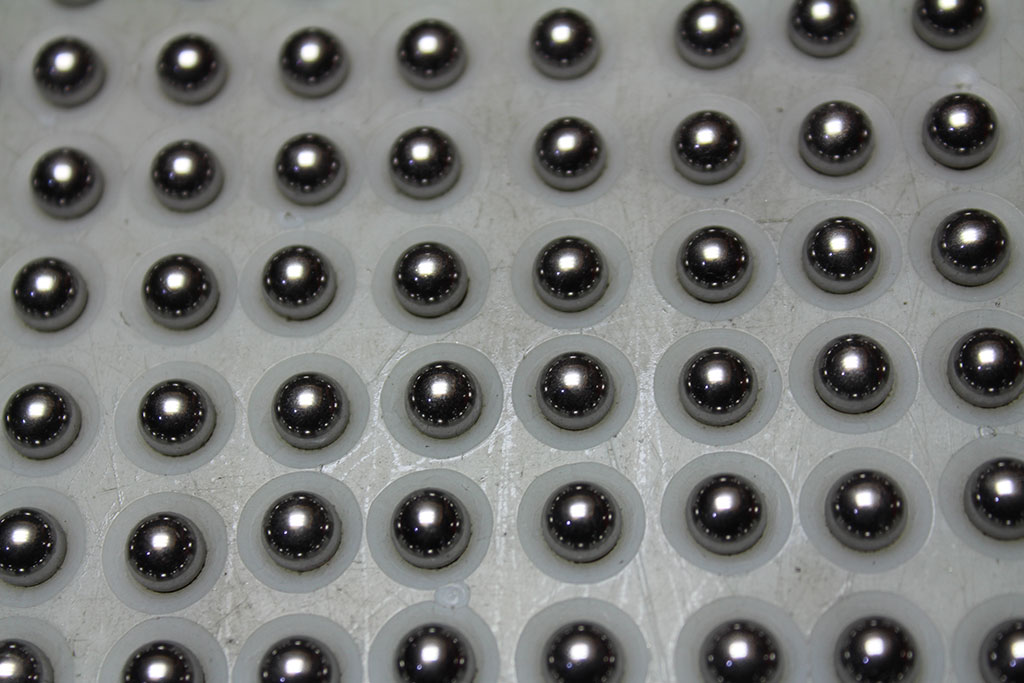

Coated Balls (Bronze, Brass, Gold)

Application: Roll-on applicators, sprays, pumps.

Industry: Cosmetic, pharmaceutical.

Our coated balls, which come in bronze, brass, silver, and gold finishes, enhance both the functionality and aesthetic appeal of your products.

These balls are commonly used in high-end cosmetic and pharmaceutical applications, where both performance and appearance are critical. The coatings provide additional corrosion protection while enhancing the visual appeal, making these balls a premium choice for luxury product lines.

Ball Valve Balls

Sizes: Available in sizes from 3/8″ to 4″ (Customizable)

Material: Any material as per operational conditions.

Industry Use: Ball valve balls are crucial in controlling fluid flow across multiple industries.

Their design ensures reliable and precise flow regulation in systems such as pipelines, water treatment facilities, and chemical processing plants. The versatility in materials and configurations allows for adaptation to various operational environments, amplifying performance and durability in industrial settings.

Industrial Steel Balls

Production capacity: 4.5 billion pieces annually.

Even in the most demanding environments,these balls provide consistent performance across automotive and aerospace applications. Our cutting-edge manufacturing facilities ensure that

Miniature Balls

Material: Stainless Steel (SS), SAE 52100, EN31.

Application: Roll-on applicators, sprays, pens, and inhalers.

Industry: pharmaceutical and cosmetics industry.

Miniature balls are essential parts of consumer goods and precision instruments. These small balls, made of high-quality stainless steel and other long-lasting materials, are ideal for applications that require precise and dependable performance.

Whether used in medical devices like inhalers or everyday items like pens, our miniature balls ensure smooth operation and long-term durability while adhering to the pharmaceutical, industrial, and cosmetic industries' strict specifications.

Satellite Balls

Application: Media components.

Industry: Abrasive industry.

Satellite balls, made from EN31 and stainless steel,

designed for use in the abrasive industry.

Their robust construction allows them to withstand harsh operating conditions, making them essential in media applications. These balls are engineered for maximum durability and efficiency, ensuring that your abrasive processes are optimized for performance and longevity.

SS Balls & Chrome Balls

Application: Steering columns, bearings, seating mechanisms.

Industry: Bearing, automotive, aerospace.

These balls are designed to withstand wear and corrosion, resulting in exceptional performance in high-stress environments. Whether in steering columns or precision bearings, they help vehicles and machinery run smoothly and safely, ensuring reliability and efficiency across a wide range of applications.

Their robust construction allows them to withstand harsh operating conditions, making them essential in media applications. These balls are engineered for maximum durability and efficiency, ensuring that your abrasive processes are optimized for performance and longevity.

Glass Balls

Application: Roll-on applicators, rust preventive sprays.

Industry: Pharmaceutical.

Glass balls are versatile components that are used in a variety of applications, including the pharmaceutical industry.

These balls, made of high-quality glass, plastic, or special ceramics, are ideal for use in roll-on applicators and anti-rust sprays. Their smooth surface and precise dimensions ensure efficient operation and consistent results, making them an ideal choice for manufacturers seeking dependable and long-lasting solutions.

Plastic Balls

Application: Roll-on applicators, sprays.

Industry: Pharmaceutical, cosmetic.

The plastic balls from SKP France come in a variety of colors to meet different functional and aesthetic needs.

They are lightweight and adaptable. Mostly utilized in the cosmetic and pharmaceutical sectors, these balls are essential to items like sprays and roll-on applicators. They are perfect for high-precision applications because of their smooth finish and reliable quality, which guarantees long-term durability and easy operation.

Coated Balls (Bronze, Brass, Gold)

Application: Roll-on applicators, sprays, pumps.

Industry: Cosmetic, pharmaceutical.

Our coated balls, which come in bronze, brass, silver, and gold finishes, enhance both the functionality and aesthetic appeal of your products.

These balls are commonly used in high-end cosmetic and pharmaceutical applications, where both performance and appearance are critical. The coatings provide additional corrosion protection while enhancing the visual appeal, making these balls a premium choice for luxury product lines.

Ball Valve Balls

Sizes: Available in sizes from 3/8″ to 4″ (Customizable)

Material: Any material as per operational conditions.

Industry Use: Ball valve balls are crucial in controlling fluid flow across multiple industries.

Their design ensures reliable and precise flow regulation in systems such as pipelines, water treatment facilities, and chemical processing plants. The versatility in materials and configurations allows for adaptation to various operational environments, amplifying performance and durability in industrial settings.