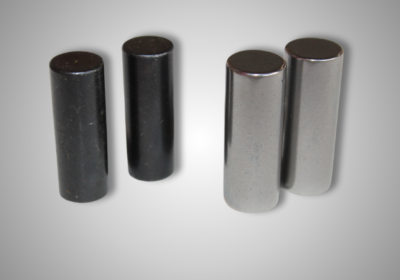

The compact size of these rollers results in a reduced radial cross-section, making them well-suited for applications with limited space. The line contact between the rollers and raceways ensures they can support high radial loads while offering enhanced rigidity.

Recognized among leading needle roller manufacturers, SKP Bearing Industries Ltd. stands for precision, quality, and customizable options.

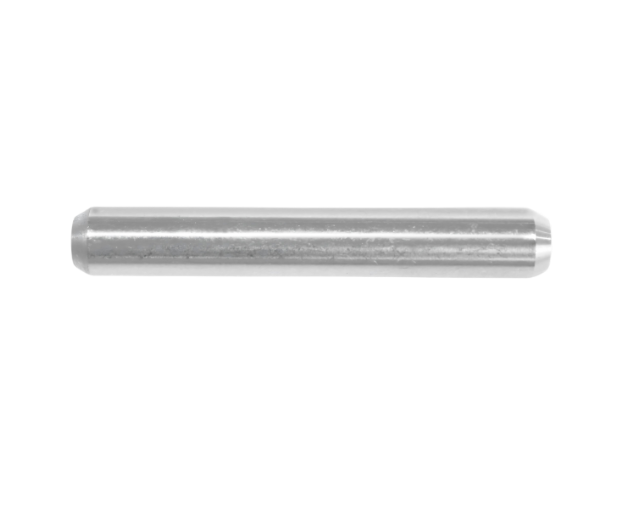

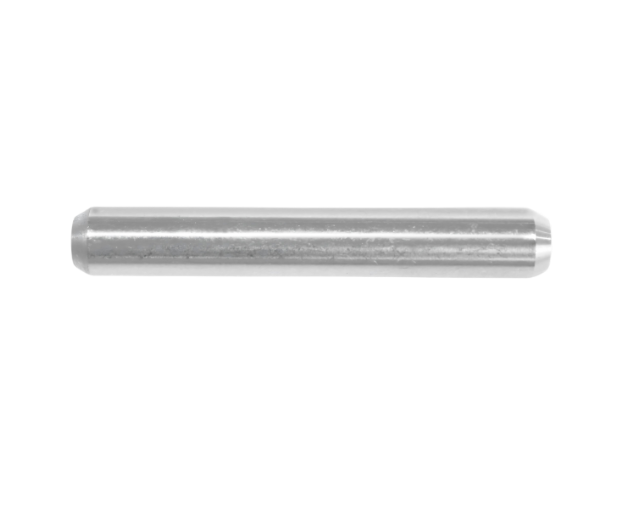

- Type BP (FLATE UNGROUND ENDS) : D(MM) : 1 to 7 mm | L(MM) : 3 to 100 mm

- Type BR (ROUNDED ENDS) : D(MM) : 1.5 to 7 mm | L(MM) : 5 to 50 mm

- Type BPM (FLATE GROUND ENDS) : D(MM) : 2.5 to 10 mm | L(MM) : 4 to 50 mm

Steel balls are vital for smooth, efficient motion in industrial machinery. Since 2018, SKP Bearing Industries Limited has been producing high-quality steel balls, ranging from 0.6 mm to 16.00 mm, using advanced machinery and rigorous quality control. Our reputation for reliability is backed by our state-of-the-art testing equipment, including roundness testers, hardness testers, diameter control instruments, and roughness testers.

Types of Needle Rollers

Single-Row

Needle Rollers

Applications:

Used in automotive transmissions, agricultural machinery, and industrial gearboxes.

Double-Row

Needle Rollers

Applications:

Suitable for heavy machinery, conveyor systems, and construction equipment.

Caged Needle

Rollers

Applications:

Found in high-speed applications like automotive engines and pumps.

Full Complement

Needle Rollers

Applications:

Ideal for slow-speed, heavy-load applications like industrial presses and heavy-duty motors.

Single-Row

Needle Rollers

Applications:

Used in automotive transmissions, agricultural machinery, and industrial gearboxes.

Double-Row

Needle Rollers

Applications:

Suitable for heavy machinery, conveyor systems, and construction equipment.

Caged Needle

Rollers

Applications:

Found in high-speed applications like automotive engines and pumps.

Full Complement

Needle Rollers

load capacity.

Applications:

Ideal for applications with slow rotational speeds and heavy loads, such as in industrial presses and heavy-duty motors.

Benefits in Industrial Applications

Difference Between BR, BP, and BPM

| Feature | BR (Bearing Roller) | BP (Bearing Plain) | BPM (Bearing Precision Machined) |

|---|---|---|---|

| Type of Bearing | Rolling-element bearing | Plain (sliding) bearing | Precision-machined rolling-element bearing |

| Load Capacity | High radial load capacity | Moderate load capacity | High load capacity with precise tolerance |

| Friction | Low due to rolling elements | Higher fr iction due to sliding surfaces | Very low,highly efficient due to precision |

| Application | Used in high-speed and heavy-load applications | Suited for low-speed, high-load applications | High-precision machinery requiring accuracy |

| Maintenance | Requires periodic lubrication | Minimal maintenance needed | Requires careful lubrication and maintenance |

| Cost | Moderate | Low | High due to precision engineering |

| Tolerance Accuracy | Standard tolerance | Low accuracy | Extremely high accuracy and tight tolerances |